In an era where precision and efficiency are paramount, the role of an advanced scale system cannot be overstated.

From manufacturing to logistics, innovative scale systems are transforming the way industries operate by providing accurate measurements and streamlining processes.

These advancements are not just about weighing things; they are about integrating sophisticated technology to ensure optimal performance and reliability.

The Evolution of Scale Systems

From Mechanical to Digital: A Brief History

Scale systems have come a long way from their humble beginnings. Initially, mechanical scales with simple levers and weights were the norm. These devices were labour-intensive and prone to errors.

However, as technology advanced, digital scales emerged, offering greater accuracy and ease of use. The transition from mechanical to digital scales marked a significant milestone, revolutionizing various industries by providing more reliable and precise measurements.

The Role of Technology in Modern-Scale Systems

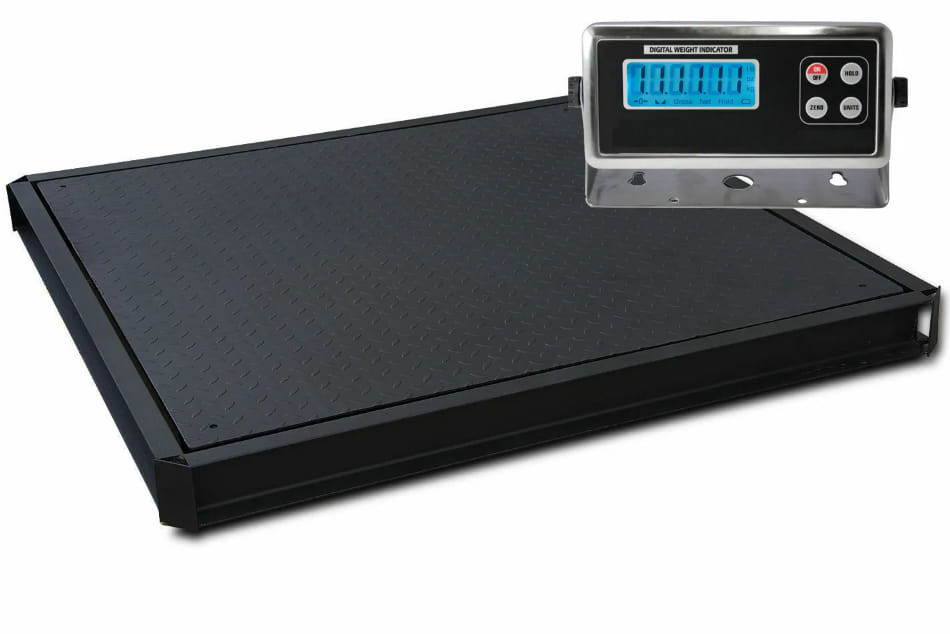

Today’s scale systems are a far cry from their mechanical predecessors. Technological advancements, such as load cells, digital displays, and connectivity features, have dramatically improved their functionality.

Load cells, for instance, convert force into an electrical signal, allowing for precise weight measurements. Digital displays provide easy-to-read results, while connectivity options like Bluetooth and Wi-Fi enable seamless integration with other business systems.

These innovations not only enhance accuracy but also make scale systems more user-friendly and versatile.

Benefits of Using Advanced Scale Systems

Improving Operational Efficiency

Modern scale systems are game-changers when it comes to operational efficiency. They provide faster and more accurate measurements, reducing the time needed for weighing processes and minimizing errors. In industries like manufacturing, where every second counts, this can lead to significant productivity gains.

Imagine a production line where every product is weighed precisely and quickly, ensuring consistency and speeding up the entire process.

Enhancing Quality Control

Advanced scale systems play a crucial role in quality control by ensuring that products meet specified weight standards. Automated data logging features allow for continuous monitoring and recording of weights, making it easier to maintain high quality and consistency.

This is particularly important in industries like pharmaceuticals and food production, where precise measurements are essential to meet regulatory standards and ensure consumer safety.

Key Features to Look for in a Modern Scale System

Precision and Accuracy

When it comes to choosing a scale system, precision and accuracy are paramount. Look for scales with high-resolution load cells and advanced calibration options.

These features ensure that you get consistent and reliable measurements every time. For businesses that rely on exact measurements for their products, having a scale that delivers pinpoint accuracy is non-negotiable.

Connectivity and Integration

Connectivity options such as Wi-Fi and Bluetooth are becoming increasingly important in modern scale systems. These features allow for seamless integration with inventory management software, production databases, and other business systems.

By enabling real-time data transfer and analysis, connected scales can help businesses make more informed decisions and improve overall efficiency.

Applications of Scale Systems in Various Industries

Manufacturing and Production

In manufacturing and production, scale systems are essential for ensuring product consistency and efficiency. They are used to weigh raw materials, track production output, and verify finished products.

For example, in the automotive industry, scale systems help ensure that parts and components meet exact specifications, reducing the risk of defects and enhancing overall product quality.

Logistics and Shipping

Scale systems are also vital in logistics and shipping. Accurate weight measurements are crucial for calculating shipping costs, managing freight, and ensuring compliance with transportation regulations.

For instance, logistics companies use scale systems to weigh packages and pallets, helping them avoid overloading vehicles and optimizing fuel efficiency. This not only reduces costs but also improves safety and reliability in the supply chain.

Conclusion

Innovative scale systems play a significant role in enhancing precision and efficiency across various industries. From improving operational efficiency and quality control to offering advanced features like connectivity and integration, these systems are indispensable tools for modern businesses.

By understanding and leveraging the benefits of advanced scale systems, industries can optimize their operations, reduce costs, and ensure compliance with regulatory standards. Investing in the right scale system is not just a good idea—it’s a smart move towards better accuracy, efficiency, and overall success.