Stainless steel fabrication is a specialised field requiring precision, expertise, and adaptability. Whether for architectural projects, industrial structures, or bespoke designs, hiring the right stainless steel fabricators can make a significant difference in the quality and longevity of your project. But what specific skills should you look for in a fabricator?

This guide highlights the essential capabilities to ensure you choose a professional who meets your needs.

1. Proficiency in Welding Techniques

One of the fundamental skills of a stainless steel fabricator is mastery over welding. Stainless steel requires precise techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding to ensure strong, clean joints without compromising the material’s corrosion resistance.

2. Design and Blueprint Interpretation

A professional fabricator must have the ability to interpret blueprints and translate designs into tangible products. This includes understanding technical drawings, material specifications, and measurements. Whether it’s a commercial kitchen bench or intricate architectural detailing, a skilled fabricator can visualise and execute the design with accuracy, ensuring the final product aligns with your vision.

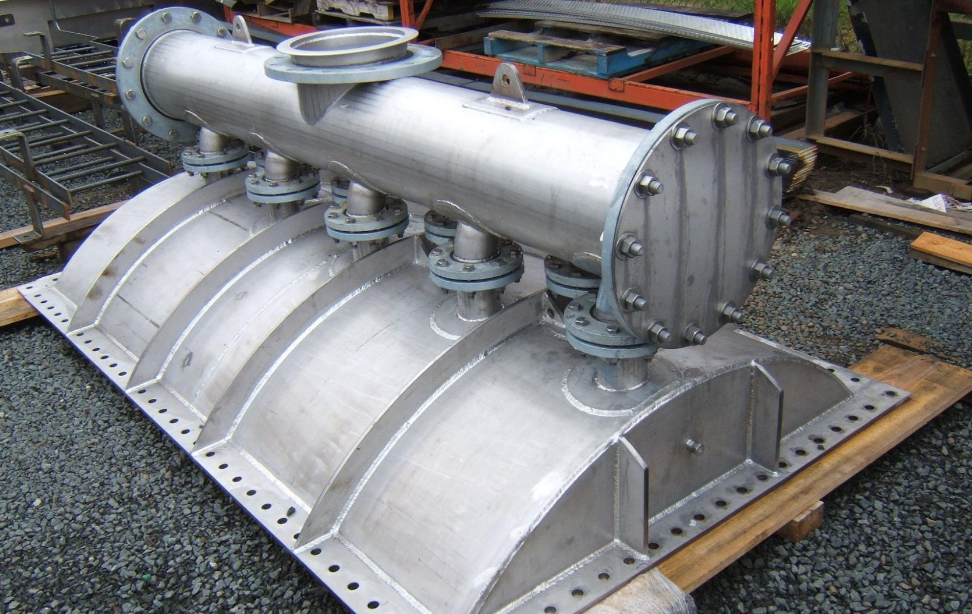

3. Expertise in Cutting and Shaping

Stainless steel is a robust yet versatile material, and fabricators must have the skills to cut and shape it effectively. Proficiency with advanced machinery, such as CNC (Computer Numerical Control) cutting tools, is crucial for achieving precision and minimising material waste. This skill ensures efficiency in the fabrication process while delivering products with exact dimensions and clean edges.

4. Problem-solving and Adaptability

Projects often encounter unforeseen challenges, such as material constraints or design changes. A competent stainless steel fabricator will have strong problem-solving skills and adaptability to navigate these issues without compromising quality. Their ability to innovate and adjust ensures your project remains on track and within budget.

5. Local Knowledge and Compliance

For clients in New Zealand, fabricators with experience in the region offer added advantages. For instance, stainless steel fabricators in Auckland are often well-versed in local building codes and environmental conditions, ensuring the product is compliant and durable in New Zealand’s climate.

The professional skills of stainless steel fabricators—from welding precision to blueprint interpretation—are essential for ensuring your project’s success. By focusing on these capabilities, you can partner with a fabricator who brings both expertise and reliability to the table, delivering results that stand the test of time.